Goto part2

My use-case for a compressor:

I need a compressor to fill up my 10L tank from 200bar to 300bar. I use a FX impact with a regulator set at 145bar. It has a cylinder of 480cc @250bar.

Time is no problem, I can wait 2 hours if needed to do the filling.

Since I am only topping up, I have no need for a PMV (in part2 I will install a bauer PMV).

I' m capable of timing 15mins to do the water draining, so no automatic stuff necessary.

I'm looking for a monthly top-up at a reasonable speed: 100bar x 10L = 1000L

I like to have guarantee for several years.

No more than 1500€

So I found this Carette Compressor at airgunheaven.com in Holland.

5 years guarantee on the compressor block

3 years guarantee on the electric motor

2 years guarantee on the other parts

25L/min fillrate -> 1000L should be done in 40 minutes. I can live with that.

|

| My Compressor with the Philadelphia option ;-) |

Specifications:

2 cylinder compressor 300bar

base model, no PMV, no automatic draining

Maintenance schedule:

| maintenance part and item | maintenance content | maintenance Period | Remarks |

|---|---|---|---|

| Compressor host | Replace lubricating oil for 0.3L |

10-20 hours

| 1st maintenance |

| Compressor host | Replace lubricating oil for 0.3L |

40-50 hours

| 2nd maintenance |

| Compressor host | Replace lubricating oil for 0.3L |

70-80 hours

| repeat |

| Air intake filtration core | Check and sweep |

60 hours

| Replace if needed |

| Oil-water filtration core | REPLACE |

20 hours

| |

| Belt | Check and adjust |

65 hours

| Replace if needed |

| Antifreezing fluids | Check and adjust |

100 hours

| replace once every 2 years |

Other reviews online:

an excellent 24hours torture test and tear-down:http://www.talonairgun.com/forum/viewtopic.php?f=52&t=35990#p371784

Some collected info after my first usage.

update 2017-04-19 : there IS a non-return valve fitted just before the oil water seperator. The manual seems to be lacking this information :)

|

| Heat signature after 10min with no load |

|

| Heat signature after 45min with 300bar load |

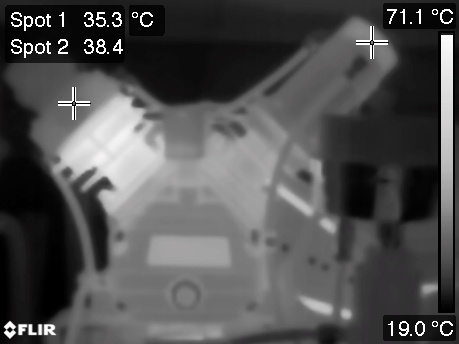

The same difference in temperature is there at full load, but no abnormal temps. The cylinder-heads themselves are staying cool due to the water-cooling passing through them. The other red marking in the picture is the belt.

|

| Temperature readings of both cylinderheads. Spot1=cylinder1 - Spot2=cylinder2 |

|

| Temperature of waterpump after 45min |

|

| Temperature of air after 2nd stage cooling, before entering the water-oil seperator |

|

| Cylinder heat only +3C after charge from 220bar to 300bar |

|

| 2.5 ml water-oil drained from system during the 35min session |

Important: After each fill you should let it do a 3-5 minute no-load run with the draining port open, to clear out any condensate water in the first cylinder!

In part2 I add a PMV to the standard model.

So are you now saying that if you have the "non- return valve" (in my case I have a PMV valve), that you dont have to wait until the compressor builds pressure equal to or greater than your tank?

ReplyDeleteFor instance....my PMV starts to let air thru the valve at approx 1800 psi....is it then safe to open the tanks valve? Even if it is sitting at 3000 psi?

It's best practice to only open your tanks valve when the pressure inside the carette is equal or higher.

DeleteIt is all about avoiding sudden pressure peak loads on the cylinders. In the case of a pmv, your pressure differential between your tank and opening pressure of the pmv will lighten the load versus not having a pmv at all.

Lets say your tank sits at 3000 psi and your pmv opens at 2000psi. There will only be a 1000 psi difference. Non pmv versions will have 3 times more!

nice review ... same question but i didn't understand it very well ...

Deleteso now let say i have PMV set at 2000psi ! my tank 3000psi should i open my tank right away or i must wait until compressor equal 3000psi or higher ?

You should wait until the compressor builds to the approximate pressure currently in your tank.... then open slowly...

Deletethank you for quick reply ... make more review about it , its very rare to find someone talkin about compressors

DeleteAfter more than a year, all is still working fine and no issues at all.

ReplyDeleteI concur!...It has run flawlessly! I rotate between 4 88c ft bottles, and I shoot a lot (a lot of big bore air hogs...plus several rifles that require 3300+ psi)....no issue's at all....

ReplyDeleteMine has gotten very slow, after 4000 From 4000 to 4500 can take 45 minutes ??? Any ideas ?? No leaks found. Even from zero, with a plug in the compressor line, it takes around 5 min to reach 4000 ???? Maybe have 10 hours. Royle Purple oil.

ReplyDeleteLooks like a leak somewhere. Have you checked each and every connection with a leak detector spray? Also on the high pressure tubing connectors on the backside.

DeleteI have a carette with 17 hours run time on it and have the same problem. IN the beginning it worked great but performance has declined getting very noticeable since about 10 hours of run time. The last time I filled my SCBA 45 minute bottle it took 1 hour to fill the last 250 PSI. No leaks.

DeleteI would recheck all your fittings because it seems that you have a leak that becomes apparent only at high pressure. Have you used a leak detector spray everywhere? I have had it once when I refitted a new connector and I only found it when using the spray. Try with a plug to eliminate as much as possible.

DeleteAbsolutely no leaks, the belt is tight. How do I contact the manufacturer directly about honoring the warranty

DeleteDo you know who the manufacturing company of this compressor is?

ReplyDeletethe manufacturer is on http://www.talonairgun.com/forum/viewtopic.php?f=52&t=35990&start=40 user "sincere" sincere4500 @ gmail.com

DeleteAm planning to purchase a fully functional Alpha-Carette compressor, Alpha air filter with necessary attachments to enable direct rifle filling, and a large air tank from Joe Brancato's Huntington Beach business location sometime soon (am hoping this week).

ReplyDeleteMade the decision to got with this compressor instead of a Daystate 110v unit after reading an in-depth tear down and mechanical inspection of the latter after reading the review in GAT; what I read impressed me greatly, enough so to buy it.

Want a dependable source of air to fill my pcp air rifles, specially the newly acquired ATI Nova Liberty .22 caliber rifle, whose air filling requirements exceeds even those of the .25 caliber FX Dreamline Classic, which itself taxes the capability limits of the Air Venturi Nomad am currently using.

Am I making a good decision by going with the A-C? Certainly hope so...

After 2 years still working fine without any issues. The unit maybe does not win any speed contests but it is stable as a rock and that's what I wanted.

DeleteThat is good to know! Am definitely buying it...

DeleteI can not recommend this compressor. I got 66 hours out of mine before deciding that it was just too much trouble to get it fixed for the second time. It has many very nice features and if it just would last I would say get one, however, mine stopped providing high presser at 13 months and then took over 1.5 years to get fixed. There isn't a support system in the US to provide parts and repair. A customer is left dealing directly with the Chinese factory to diagnose problems. I found this situation to be totally unsatisfactory. My unit died again at the 66 hour mark at which point I decided to give it away for parts and to get something else that is supported in the US.

ReplyDeleteI can not recommend this compressor. I got 66 hours out of mine before deciding that it was just too much trouble to get it fixed for the second time. It has many very nice features and if it just would last I would say get one, however, mine stopped providing high presser at 13 months and then took over 1.5 years to get fixed. There isn't a support system in the US to provide parts and repair. A customer is left dealing directly with the Chinese factory to diagnose problems. I found this situation to be totally unsatisfactory. My unit died again at the 66 hour mark at which point I decided to give it away for parts and to get something else that is supported in the US.

ReplyDeleteLocal Support is an important factor to consider when buying any compressor. I ordered all spare sparts for the cylinders in advance just in case from the factory even.

ReplyDelete